PLEASE WAIT

Your cart is empty

Check our products to find what you need, add it to your cart and request an offer.

As part of our continuous efforts to enhance the efficiency and precision of our manufacturing processes, we have recently integrated KEM-TOUCH-P2 dosing modules from the esteemed German company KOCH into the additional equipment lineup of our newly acquired Arburg injection machines.

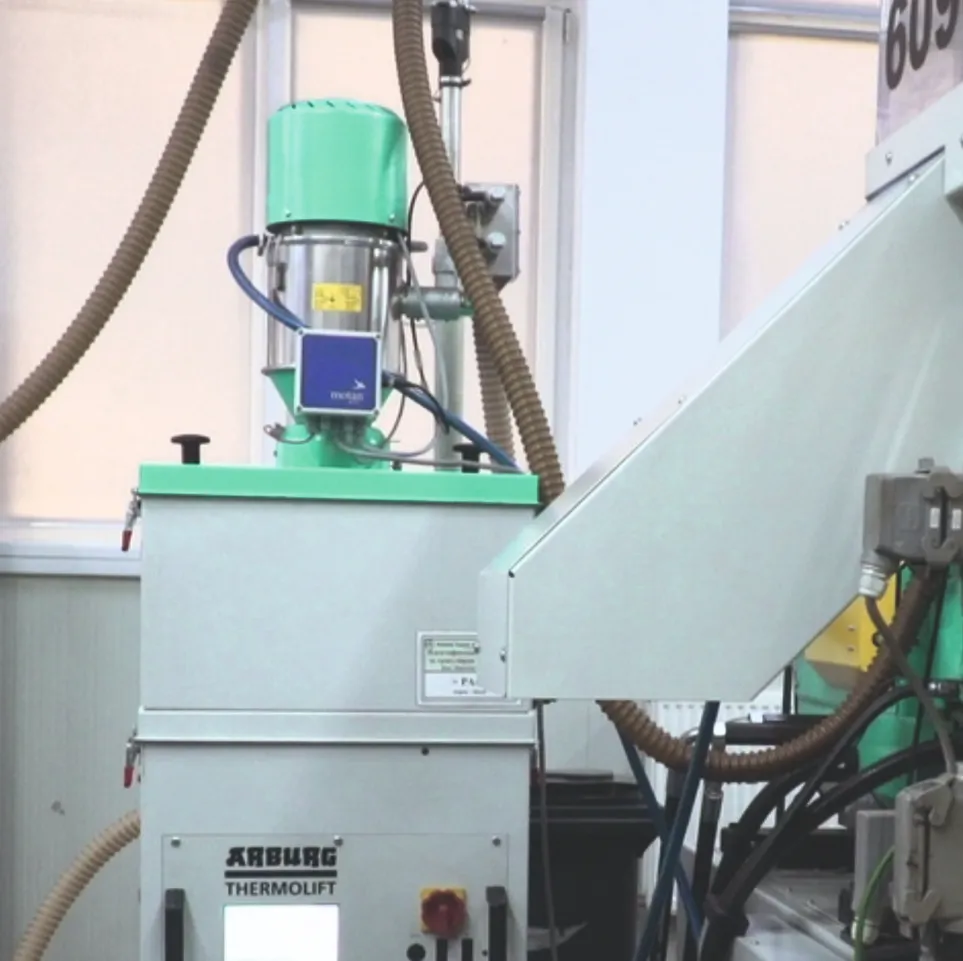

Recognizing the challenge posed by the hygroscopic nature of industrially used polymers, our facility has adopted Arburg's THERMOLIFT drying systems. These advanced drying units play a crucial role in preparing polymers for the injection molding process, ensuring they are properly dried to achieve optimal product quality.

The integration of robotic manipulators into our injection molding operations represents a significant leap forward in efficiency and precision. In our pursuit of optimizing the plastic injection molding process, we have equipped a majority of our newly acquired Arburg machines with advanced robotic manipulators.

As part of our continuous efforts to enhance the efficiency and precision of our manufacturing processes, we have recently integrated KEM-TOUCH-P2 dosing modules from the esteemed German company KOCH into the additional equipment lineup of our newly acquired Arburg injection machines.

Polycarbonate (PC) is a transparent thermoplastic and its high strength makes it resistant to impact and fracture. It is lightweight so an excellent alternative to glass. It is widely used owing to its eco-friendly processing and recyclability. PC is popularly used as an engineering plastic owing to its unique features that include: High impact strength; High dimensional stability; Good electrical properties amongst others.

Acrylonitrile Butadiene Styrene (ABS) is an impact-resistant engineering thermoplastic. It is an amorphous polymer. It is made of three monomers: acrylonitrile, butadiene, and styrene. It is a preferred choice for structural applications due to its physical properties. These properties include high rigidity, resistance to impact, abrasion, and strain. Used in electronic housings, auto parts, consumer products, pipe fittings, toys and sealing elements.

Polyamides or nylons are considered high-performance plastics. They exhibit high temperature & electrical resistances. They find their use in the automotive, transportation, consumer goods, and electrical and electronics industry. Several types of polyamide chemistries are available in the market today. PA 6 & PA 6-6 are by far the most used polyamides globally. They are used in many applications due to their excellent performance/cost ratios. Their key properties include: high strength and stiffness at high temperature; good impact strength, even at low temperature; excellent fuel and oil resistance; good electrical insulating properties; High water absorption and water equilibrium content limit the usage so proper drying before processing is needed.

If there is question about items being durable and cost-effective so polypropylene (PP) would be the star among all commodity plastics. This lightweight thermoplastic is tough, rigid, crystalline, and comes in many forms. Polypropylene (PP) is a type of polyolefin, that is slightly harder than polyethylene. It is a commodity plastic with low density and high heat resistance. It finds application in packaging, automotive, consumer goods, medical, cast films, etc.

Polyvinyl Chloride (PVC or Vinyl) is a high-strength thermoplastic material. It is widely used in applications such as pipes, medical devices, and wire & cable insulation...the list is endless. It is the world's third-most widely produced synthetic plastic polymer. The reason is due its properties such as: lightweight, durable, low cost, and easy processability.

PBT, Polybutylene Terephthalate, belongs to the family of polyester thermoplastics. PBT is a semi-crystalline polymer used mainly in injection moulding for engineering applications. Key Polybutylene Terephthalate (PBT) properties: high strength; high continuous service temperature (up to 150°C); high rigidity and hardness; high dimensional stability; no environmental stress cracking, etc. PBT (Polybutylene Terephthalate) typical applications are: electrical and electronic parts, automotive parts, appliance parts.